When it comes to the procurement of cable equipment, the extruder holds significant importance for wire and cable enterprises. Here are some aspects to consider when purchasing and selecting an extruder machine:...

In the process of machine production, inevitable consumables wear and aging of parts will always be encountered, and long-term accumulated damage will eventually be exposed to problems. How to solve these common mechanical problems? This article provides you with the answer...

The wire drawing machine industry is experiencing improved development prospects. However, it is important to address certain challenges related to equipment damage, heating processes, fire risks, and exhaust gas pollution, which can lead to safety accidents....

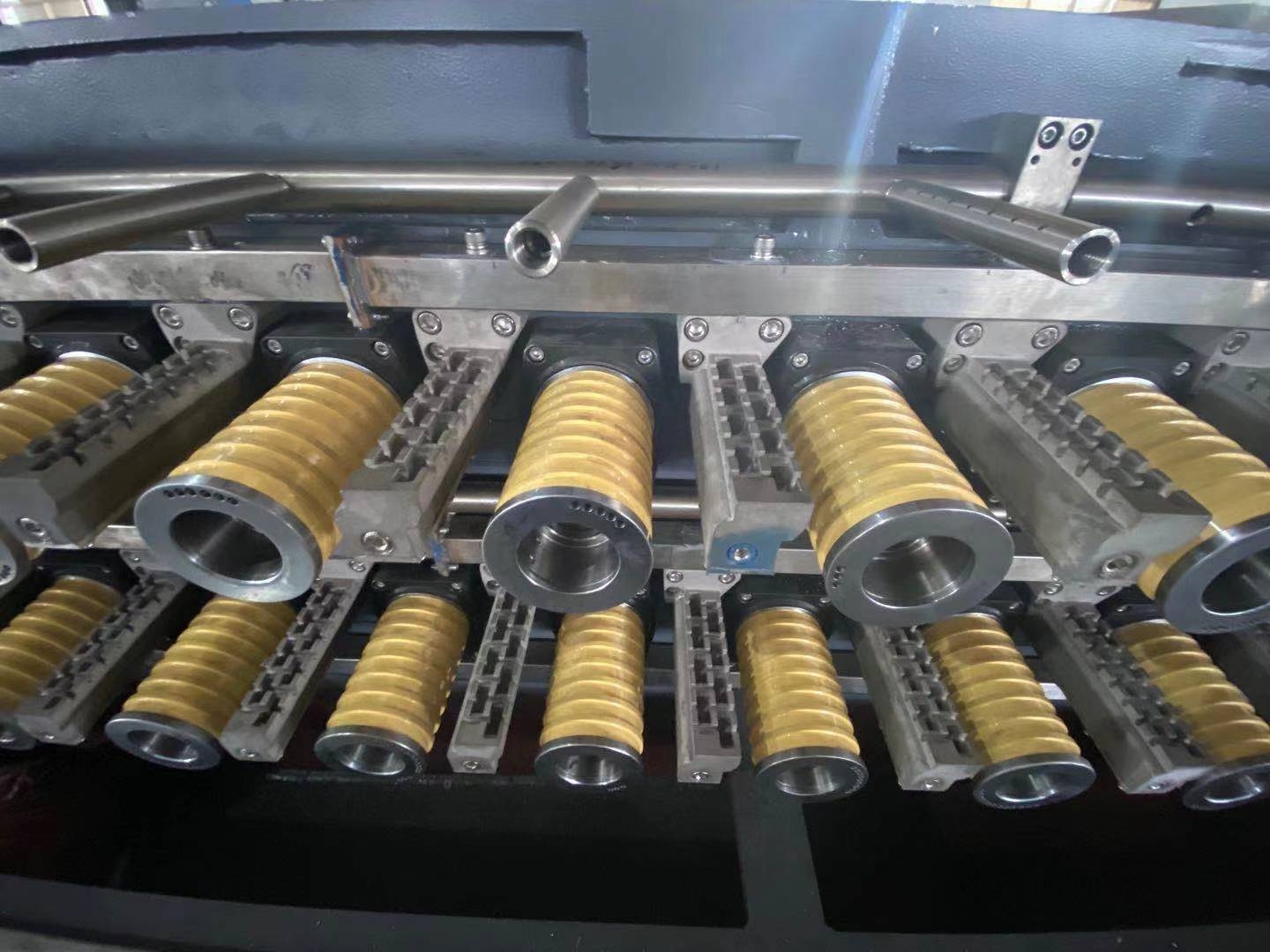

In the wire drawing process, proper lubrication is essential to improve the drawing effect and control temperature to prevent oxidation. There are three common methods of lubrication used in wire drawing machines: single die groove dispersion lubrication, immersion lubrication, and circulating lubrication system....

In the wire drawing process using a flat wire drawing machine, the workpiece is conveyed by a conveyor belt and passed through a rotating non-woven roller brush. The roller brush rotates at high speed to draw the surface of the workpiece, creating a continuous thread pattern....

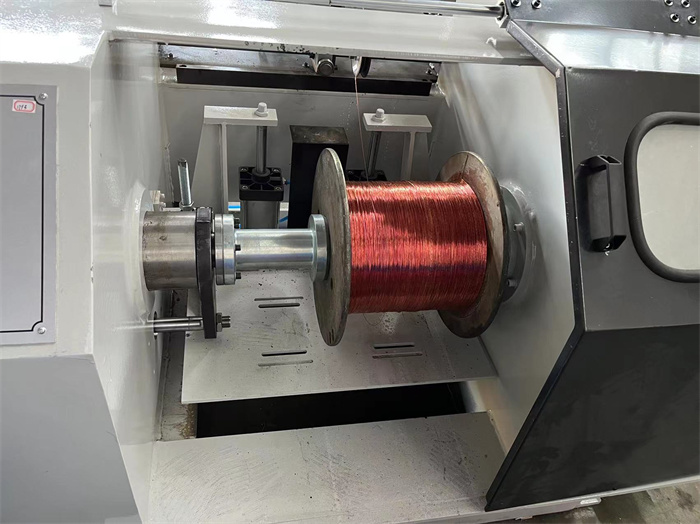

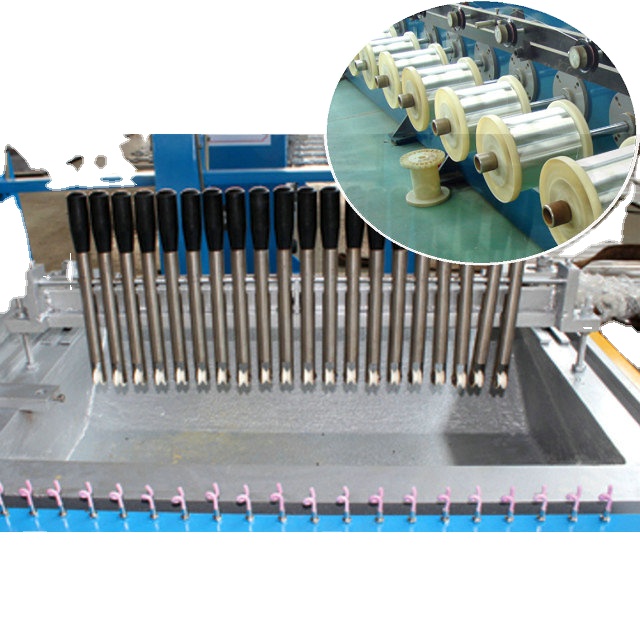

Currently, traditional small copper alloy wire drawing machines or miniature wire drawing devices are often controlled by synchronous motors and 2-position limit switches. In the wiring process, operators need to constantly adjust the wire margin. The wire take-up machine typically consists of an iron plate and an ABS plastic disc. For small machines, an ABS plastic disc is commonly used to take up the wire....

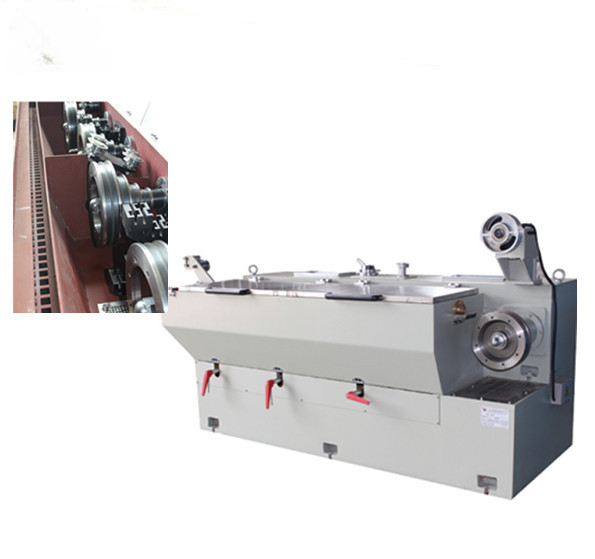

However, based on the description you provided, it seems that the inverted wire drawing machine is a specialized device designed for high-speed and high-precision wire drawing operations. It utilizes a complex system and requires coordination among multiple motors....

During operation, the inverted wire drawing machine requires precise and high-speed control, which necessitates the use of special mechanical devices to ensure accurate and smooth line speed....

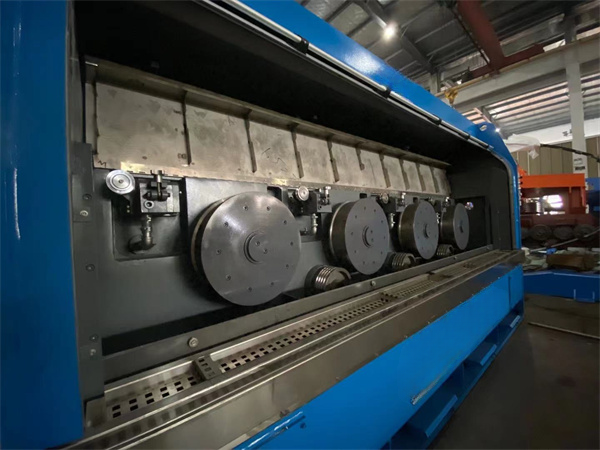

The water tank wire drawing machine has unique features compared to other similar equipment. During the drawing process, there is relative sliding between the wire and the coil. Additionally, the machine operates with the involvement of steel wires, reels, and wire drawing dies immersed or sprayed with cooling lubricating liquid....

Here's a summary of the characteristics you mentioned: LT Type Water Tank Wire Drawing Machine: Diameter range of finished wire drawing: 0.1-1.2mm Working characteristics: Sliding wire drawing, multi-pass drawing...

When using a flat wire drawing machine to wire the product, sometimes there will be defects such as coarse grains, fine sandpaper marks, and flow marks on the surface....

At present, many production plants are equipped with wire drawing machines, so the water mill wire drawing machine brings many advantages to factory applications....