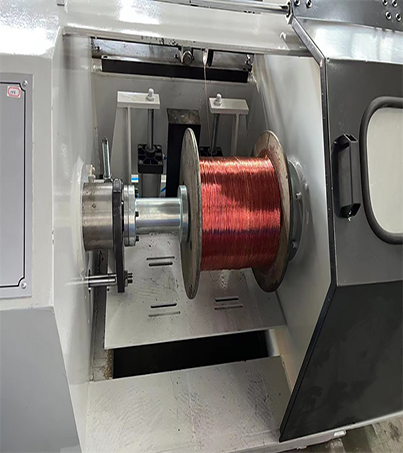

Pay-off Diameter Range: The machine is designed to handle wire diameters ranging from Ø0.8mm to Ø4.0mm for pair twisting. This versatility allows for the processing of a wide range of wire sizes commonly used in various applications. Back-Twist Direction: The machine offers the option to choose between S (sinistral) or Z (dextral) back-twist directions. This flexibility allows for the production of twisted wire pairs with different twist orientations, depending on the specific requirements of the application.

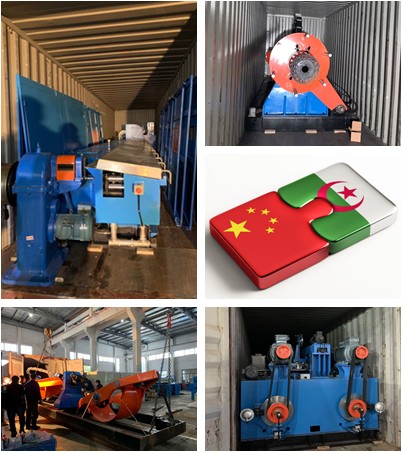

BACK TWIST MACHINE

Machine Dimensions and Weight: The overall dimensions of the machine are L2100mm × W1680mm × H1420mm. It has a net weight of 1850kg, providing a stable and robust construction that can withstand the demands of the wire twisting process.

Technical parameter:

| Type | 400 Back Twist Machine | 500 Back Twist Machine | 630 Back Twist Machine |

| Applicable wire Dia. | Φ0.8mm-Φ4.0mm | Φ0.8mm-Φ4.0mm | Φ0.8mm-Φ4.0mm |

| Reel Dia. | Φ400mm | Φ500mm | Φ630mm |

| Retreat direction | Exchange wrapping direction S or Z | ||

| Tension range | 100g-3000g | ||

| Power | 5HP | ||

| Machine dimension | L2100×W1680×H1420 (According to the number of the wire) | ||

| Net weight | 1850KG (According to the number of the wire) | ||

Inquire Form