Wire Preparation: Prepare the wires that will be used for the twisting process. This may involve straightening the wires and ensuring they meet the required specifications for diameter, insulation, and conductor material. Twisting Setup: Set up the machine according to the desired configuration, whether it is for double layer or single layer continuously center wrapping. Adjust the machine settings, such as the wire feed speed and twist pitch, to achieve the desired twisting pattern.

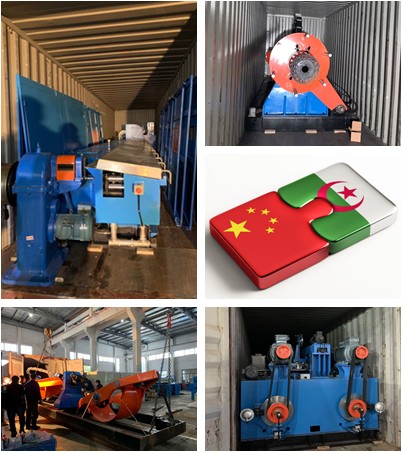

Double Layer Multi Layer Wrapping Machine

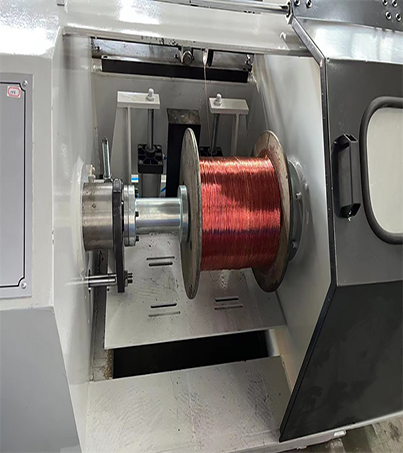

Take-Up: After the twisting process is completed, the twisted wires can be wound onto spools or reels using the take-up system. This allows for easy storage, transportation, and further processing of the twisted wire products.

Technical parameter:

Inquire Form