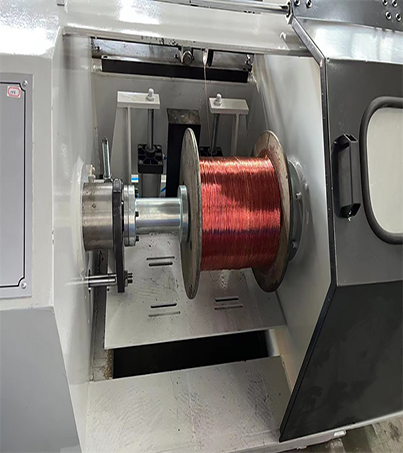

Double Tank Design: The machine features a double tank design, allowing for the simultaneous tinning of 20 wires in each tank. The two tanks can be used individually, providing flexibility and increased production capacity. Tank Material: The tanks are made of FC25 casting, which is a durable and robust material known for its strength and resistance to heat and corrosion. This ensures the longevity and reliability of the machine.

Wire Hot Dip Tin Coating Machine

Tinning Tank Heating and Temperature Control: The machine employs a special high-temperature quilt cover furnace body for heating and temperature control of the tinning tanks. This design ensures efficient heat transfer and precise temperature regulation during the tinning process.

Tinning Wire Wheel: The tinning wire wheel is a heat-sintered alumina wheel. This type of wheel provides excellent heat resistance and durability, enabling smooth and efficient tinning of the wires.

Tinning Die: The tinning die is made of a titanium shell with an outer diameter of 25mm and a thickness of 6-10mm. The tinning die is not included with the machine and should be prepared by the buyer. The titanium shell ensures durability and resistance to high temperatures, maintaining the quality of the tinning process.

Technical parameter:

|

Wire dia (mm) |

0.08~0.32 |

0.1~0.65 |

0.1~0.7 |

|

Pressure regulator (kw) |

0.75 |

||

|

Pay-off stand |

Brush or overhead |

||

|

Tinning type |

Hot coating |

||

|

Max speed (m/min) |

300m/min |

||

|

Pay-off bobbin size (mm) |

φ300mm |

||

|

Take-up bobbin size |

5’’~8’’ |

5’’~10’’ |

5’’~10’’ |

Inquire Form