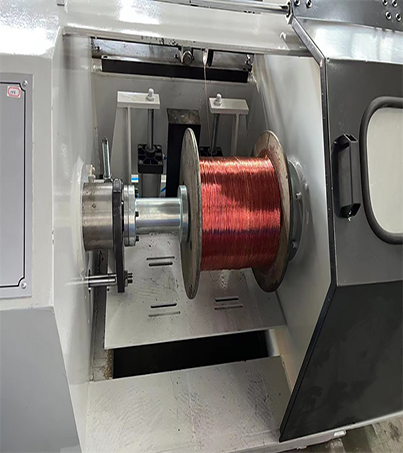

Pay Off and Twisting: The twisting machine is designed to work in conjunction with a pay-off unit, allowing for the continuous twisting of CAT5, CAT5e, and CAT6 network wires in pairs. This integrated setup streamlines the production process and ensures efficient wire twisting.

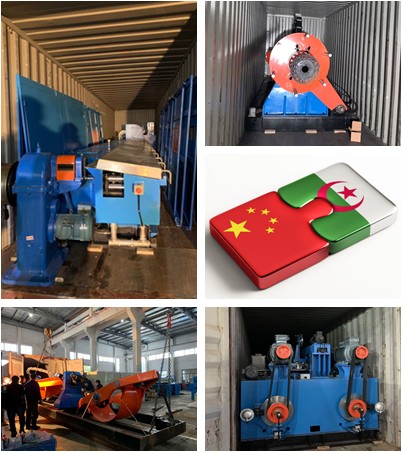

Twisting Machine + Double Head Backing Twisting Pay Off

Close-End Protective Equipment: The machine is equipped with all necessary safety features and close-end protective equipment. This ensures a high level of operator safety while operating the machine at high speeds. The protective equipment helps prevent accidents and ensures a safe working environment during the wire twisting process.

| Modle | 500 Twisting Machine |

| Max. speed | 3000rpm |

| Range of pitch | 7-50mm |

| Pitch change | Change gear |

| Twisting direction | S & Z |

| Cable type | Leveraged |

| Reel up and down | Motor-driven |

| Main motor power | 4kw |

| Electrical control | 380V 50Hz Converter |

| Figuer dimension | 2650×1250×1270mm |

|

|

|

| Modle | 500 Backing Twising |

| Max. speed | 1000rpm |

| Backtwisting radio | commend 30-35% |

| Pay off tension | adjustable |

| Backtwisting direction | S & Z |

| Reel up and down | Motor-driven |

| Main motor power | 3.7kw |

| Pay off motor power | 0.75×2 |

| Electrical control | 380V 50Hz PLC+ Converter |

| Figuer dimension | 2100×1680×1420mm |

Inquire Form