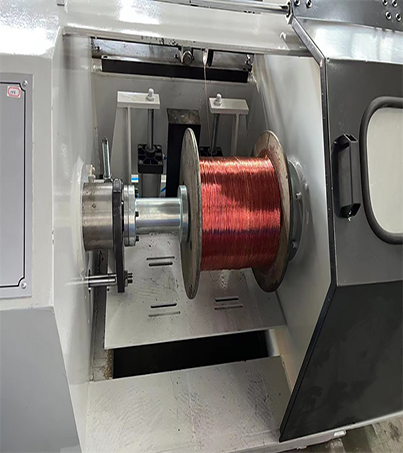

Dual Tinning Tank Design: The machine is equipped with a dual tinning tank design, allowing for the simultaneous production of two kinds of tin-coated copper wires. This feature enhances productivity and efficiency by enabling the processing of different wire types simultaneously.

Offline Annealing And Tin-coating Machine

Technical parameter:

|

Machine type

|

JCJX-32H/3.5

|

JCJX-40H/4.5

|

JCJX-40H/6

|

JCJX-40H/7.5

|

|

NO. of wire

|

32

|

40

|

40

|

40

|

|

Wire Dia. (mm)

|

Φ0.03~Φ0.08

|

Φ0.08~Φ0.32

|

Φ0.10~Φ0.65

|

Φ0.1~Φ0.7

|

|

Pay-off stand

|

Brush

|

Brush or overhead

|

|

Max. speed(m/min)

|

300

|

|

Annealing type

|

Radiation heating

|

|

Tinning type

|

Hot coating

|

|

Pay-off Bobbin Size(mm)

|

Φ250

|

Φ300

|

|

Take-up type

|

spooler drive by torque motor

|

|

Traverse type

|

Motor + inverter control

|

|

Take-up bobbin size

|

4″~5″

|

5″~8″

|

5″~10″

|

5″~10″

|

|

total power(KW)

|

50

|

50

|

65

|

75

|