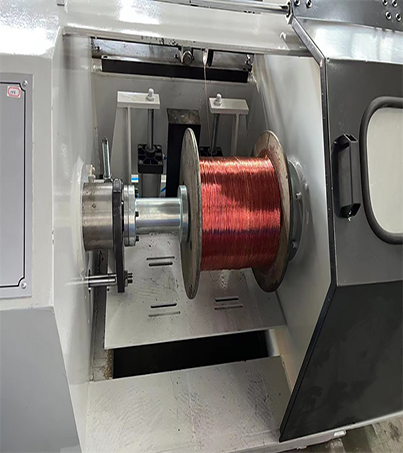

Double Inverter Auto Tension Control System: Our machine is equipped with a double inverter auto tension control system, which ensures precise and consistent tension control during the wire drawing process. This feature enhances the quality and accuracy of the drawn wire, minimizing variations and ensuring optimal performance.

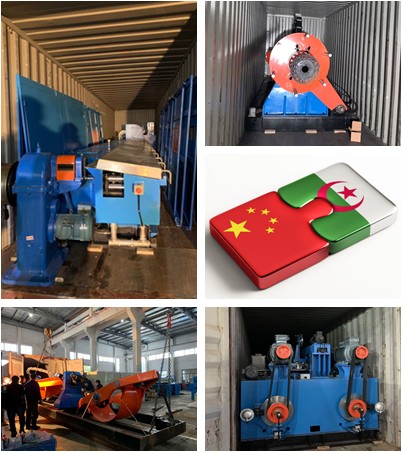

Al Intermeidate Wire Drawing Machine

Versatile Compatibility: Our machine is designed to be compatible with various additional equipment. It can seamlessly integrate with continuous annealers, take-up machines with or without shafts, and coiler machines. This versatility allows for a wide range of wire production applications, providing flexibility and convenience to meet different production needs.

usage: It is used for drawing intermediate al wire

Technical parameter:

Inquire Form