Screw Cylinder: The production line utilizes a screw cylinder made of high-quality steel, specifically No.3 GH113 (or equivalent material) with excellent resistance to high temperatures and corrosion. This ensures durability and reliable performance during the extrusion process.

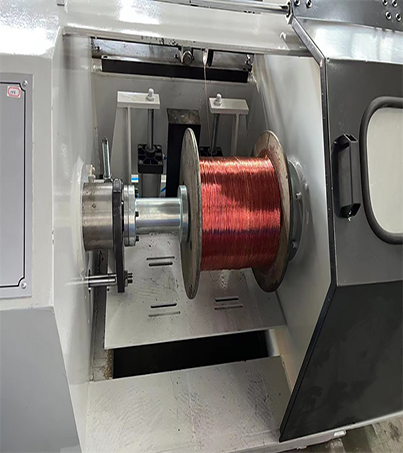

Extremely fine teflon cable extrusion production line

Quality Control: The production line includes features for quality control. It incorporates an outer diameter detection feedback device, allowing for real-time monitoring and control of product dimensions. Additionally, parameters such as concentricity are closely regulated to maintain product quality.

Electrical Control: The production line utilizes an imported conversion system along with a touch screen interface for electrical control. This advanced control system provides precise control over various parameters, facilitating efficient operation and adjustments.

Technical parameter:

| Type | JCJX-15 | JCJX-20 | JCJX-25 | JCJX-30 | |

| Core diameter (mm) | AWG46-40 | AWG42-36 | AWG40-32 | AWG40.5-3.0 | |

| Screw length/diameter | 25:1 | 25:1 | 25:1 | 25:1 | |

| Temperature control | 3+2 | 3+2 | 3+2 | 3+2 | |

| Heating power | 5 | 6 | 8 | 12 | |

| Main servo motor(kw) | 3 | 3 | 4 | 5 | |

| Traction servo motor(kw) | 1.3 | 1.3 | 1.3 | 2 | |

| Max extrusion capacity(kg/h) | 2.5 | 5 | 8 | 13 | |

| Max line speed(m/min) | 150 | 180 | 180 | 180 | |

| Accumulate length (m) | 100 | 100 | 100 | 100 | |

| Pay-off | Shaft active pay-off, with tension indicating, wire breaking protection | ||||

| Take-up | Double shaft take-up, 1.5 kw motor with inverter control | ||||

| Size (m) | 8×1.2×2.1 | 8×1.4×2.1 | 9×1.6×2.1 | 12×1.8×2.1 | |

| Weight (T) | 3 | 3.5 | 4 | 5 | |

Inquire Form