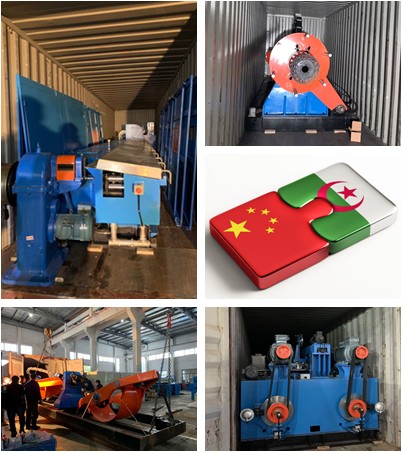

The Rod Breakdown Machine is used for high-speed drawing of copper, aluminum, or alloy rods. It features individual motor control for precise and efficient wire production. It is widely employed in wire manufacturing processes to reduce rod diameters and produce wires of various sizes.

LSD450 Non-slip Rod Breakdown Machine

The adjustable tension rate enables customization based on the specific material being drawn, ensuring optimal drawing conditions for different types of wires. Additionally, the single motor transmission facilitates fast die changes, improving operational efficiency and reducing downtime.

Technical parameter:

|

Machine type

|

LSD 450/13

|

LSD450/11

|

LSD450/9

|

|

Drawing capstan dia. (mm)

|

450

|

450

|

450

|

|

Max. Die No.

|

13

|

11

|

9

|

|

Inlet dia. (mm)

|

Copper

|

8

|

|

Al, Al alloy

|

9.5

|

|

Outlet dia. (mm)

|

Copper

|

1.2-4.2

|

1.5-4.2

|

2.0-4.2

|

|

Al, Al alloy

|

1.7-5.0

|

2.2-5.0

|

2.8-5.0

|

|

Max. drawing speed (m/s)

|

30

|

25

|

20

|

|

Single motor power (KW)

|

37/55 (AC)

|

|

Capstan arrangement

|

Horizontal type

|

|

Lubrication type

|

Full immersion

|

|

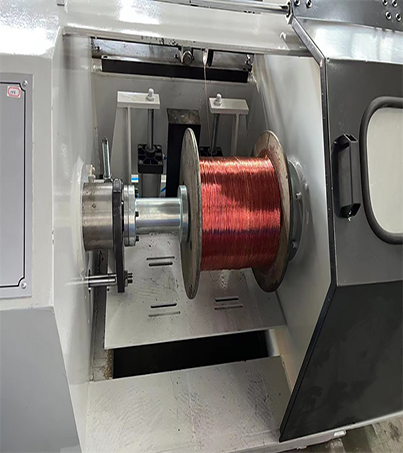

Take-up type (optional)

|

Double take-up/single take-up/orbital coiler

|

|

Optional equipment

|

On-line horizontal annealer

|

|

On-line continuous annealing device

|

|

Machine type

|

450T

|

450TB

|

|

Annealing wire dia. (mm)

|

1.2-3.5

|

1.2-4.2

|

|

Annealing voltage (V)

|

0-60

|

0-60

|

|

Annealing current (A)

|

0-6000A (DC)

|

0-5000A (AC)

|

|

Max. annealing speed (m/s)

|

25 m/s

|