The production line you described is suitable for the manufacturing of various types of low consumption wires, coaxial cables, communication cables, and transmission cables.

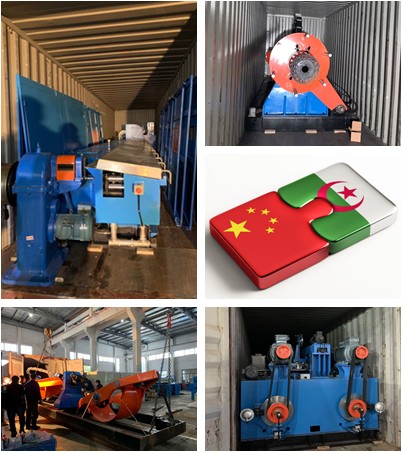

Physical Foaming Cable Extrusion Line

Quality Control: Conduct quality control checks at various stages of the production process to ensure the cables meet the required specifications. This may involve monitoring the dimensions, electrical properties, insulation thickness, and overall quality of the cables.

Optional Parts: Depending on the specific cable requirements, you can incorporate optional parts such as sparking machines, diameter-testing laser gauges, or LSZH screws to enhance quality control and performance.

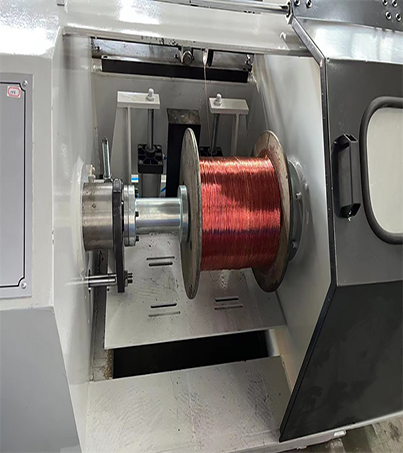

Take-Up: After the extrusion process, the finished cables are wound onto spools or reels using the take-up system. This allows for easy storage, transportation, and further processing of the cables.

Technical parameter:

Inquire Form