The production line you described is well-suited for the manufacturing of high-temperature silicone rubber cables and high-temperature sheaths

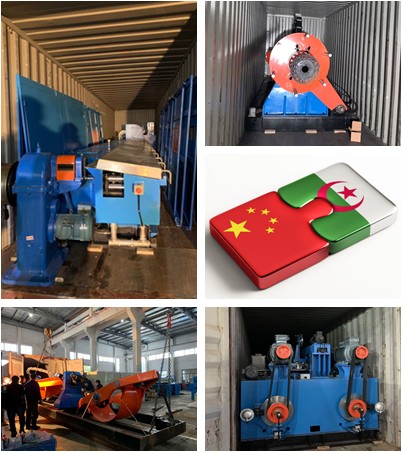

Silicone Rubber Cable Extrusion Production Line

Quality Control: Throughout the production process, it is important to conduct quality control checks to ensure that the cables and sheaths meet the required specifications. This may involve monitoring the dimensions, thickness, and overall quality of the insulation layer, as well as conducting tests to verify the high-temperature performance.

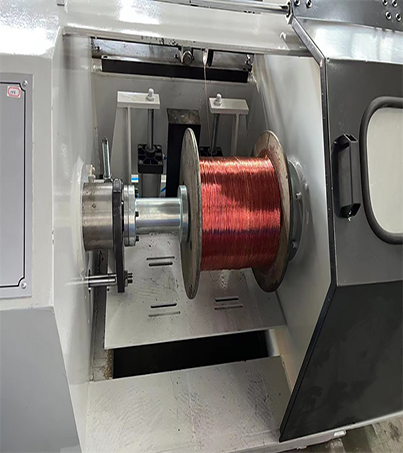

Take-Up: The finished high-temperature silicone rubber cables and sheaths are wound onto a spool or reel using the take-up system. This allows for easy storage, transportation, and further processing of the products.

Technical parameter:

Inquire Form