Precise Screw Design: The screw in the main machine is precisely designed to ensure optimal extrusion performance, promoting consistent output and quality.

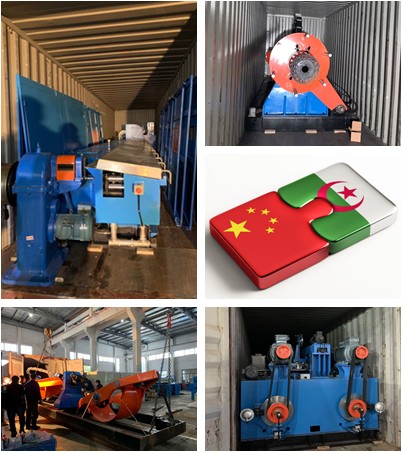

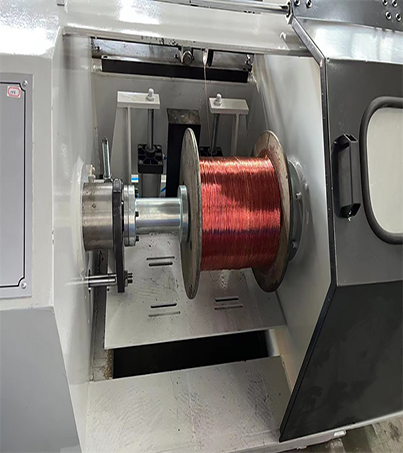

Cable sheath production line

Touch Screen + PLC Control: The production line is equipped with a user-friendly touch screen interface and PLC control system, facilitating easy operation, monitoring, and adjustment of production parameters.

Enhanced User Experience: The production line incorporates features designed to enhance user experience and improve overall efficiency.

Technical parameter:

| Type | Screw Parameters |

|

Power | Discharge Dia.(mm) |

|

|

Haul-off Unit |

|

|

|||

|

|

Dia.(mm) |

L/D Ratio |

Ratation Speed (r/min) |

Extrusion Capacity kg/h |

Main Motor Power (kw) |

|

Finished Wire Dia.(mm) | Bobbin Dia.(mm) | Front caterpilar haul-off | back caterpilar haul-off | Line Speed (m/min) | Consisting Componets |

| JCJX-70 Extrusion | Φ70 | 25:1 | 100 | 130 | 30 | 3-15 | 4-30 | 630-1250 |

|

800 | 5-200 | Pay-off/straightening/Extruder/Water trough/Haul-off/Accumulator/Take-up |

| JCJX-80 Extrusion | Φ80 | 25:1 | 95 | 180 | 75 | 3-20 | 4-40 | 800-1600 |

|

1250 | 5-180 | Pay-off/straightening/Extruder/Water trough/Haul-up/Accumulator/Take-up |

| JCJX-90 Extrusion | Φ90 | 25:1 | 90 | 280 | 90 | 3-35 | 4-45 | 800-1600 | 500 | 1250 | 10-150 | Pay-off/straightening/Extruder/Water trough/Haul-up/Accumulator/Take-up |

| JCJX-100 Extrusion | Φ100 | 25:1 | 85 | 330 | 110 | 4-50 | 5-60 | 1000-2000 | 800 | 1600 | 10-120 | Pay-off/straightening/Extruder/Water trough/Haul-up/Take-up |

| JCJX-120 Extrusion | Φ120 | 25:1 | 80 | 420 | 132 | 8-70 | 8-80 | 1250-2500 | 1250 | 2000 | 10-90 | Pay-off/straightening/Extruder/Water trough/Haul-up/Take-up |

| JCJX-150 Extrusion | Φ150 | 25:1 | 70 | 780 | 160 | 8-100 | 15-120 | 1600-3150 | 2000 | 2500 | 10-60 | Pay-off/straightening/Extruder/Water trough/Haul-up/Take-up |

| JCJX-200 Extrusion | Φ200 | 25:1 | 60 | 1000 | 250 | 30-140 | 35-145 | 1600-3150 | 2500 | 3150 | 2-60 | Pay-off/straightening/Extruder/Water trough/Haul-up/Take-up |

Inquire Form