Material Selection: Choose PVC or PE as the insulation material based on the requirements of the flat wire. PVC is known for its excellent electrical insulation properties, mechanical strength, and resistance to chemicals. PE, on the other hand, offers good flexibility, moisture resistance, and thermal stability.

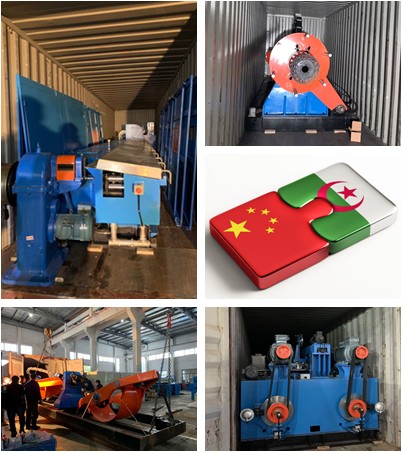

Al-alloy Flat Wires Aluminium Continous Extrusion Machine

Quality Control: Throughout the production process, it is important to conduct quality control checks to ensure that the flat wire meets the required specifications. This may involve monitoring the dimensions, thickness, and overall quality of the insulation layer.

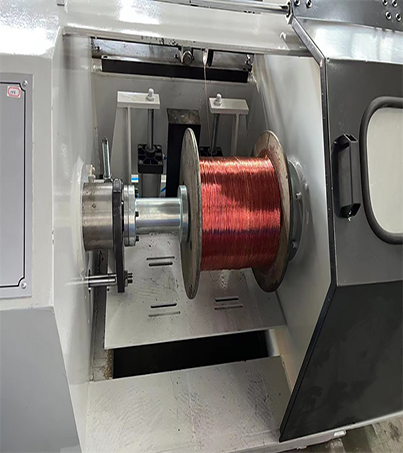

Take-Up: The finished PVC or PE insulated flat wire is wound onto a spool or reel using the take-up system. This allows for easy storage, transportation, and further processing of the flat wire.

Technical parameter:

Inquire Form