These materials are commonly used for providing insulation and protection to the conductors within the wire and cable.

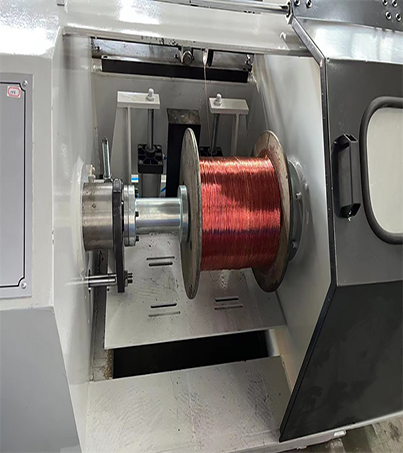

High Speed Wire Insulation Production Line

Double Layer: Additionally, the production line can be configured to apply a double insulation layer. This feature allows for the production of cables with enhanced protection and specific properties. The double layer configuration provides an additional layer of insulation and can be particularly useful for applications that require improved electrical performance, increased durability, or specialized functionality.

Technical parameter:

|

Model

|

Screw Parameters

|

Extrusion

Capacity

(kg/h)

|

Power

(kw)

|

Finished

WireDia.

(mm)

|

Pay-off

Unit

|

Line Speed

(m/min)

|

|

Dia.

(mm)

|

L/DRatio

|

Rotation

Speed

(r/min)

|

PVC

|

LDPE

|

PP

|

Main

Motor

Power

|

Total

Power

|

|

Bobbin

Dia.(mm)

|

Power

(kw)

|

|

|

JCJX-30Extrusion

|

30

|

25:1

|

20-110

|

25

|

16

|

13

|

5.5

|

21

|

0.2-1

|

300/400

|

2.2

|

10-650

|

|

JCJX-40Extrusion

|

40

|

25:1

|

20-110

|

40

|

20

|

17

|

7.5

|

24

|

0.4-3

|

300/500

|

3.7

|

10-650

|

|

JCJX-50Extrusion

|

50

|

25:1

|

20-110

|

80

|

40

|

34

|

11

|

28

|

0.8-5

|

400/630

|

3.7

|

10-650

|

|

JCJX-60Extrusion

|

60

|

25:1

|

15-110

|

100

|

53

|

41

|

18.5

|

42

|

1-8

|

500/630

|

3.7

|

10-650

|

|

JCJX-70Extrusion

|

70

|

25:1

|

15-110

|

130

|

86

|

68

|

22-37

|

50

|

2-12

|

500/630

|

|

10-350

|

|

JCJX-80Extrusion

|

80

|

25:1

|

10-90

|

200

|

122

|

96

|

30-55

|

65

|

3-25

|

500/630

|

|

10-350

|

|

JCJX-90Extrusion

|

90

|

25:1

|

10-80

|

240

|

133

|

124

|

37-75

|

75-113

|

5-35

|

630/800

|

|

10-250

|