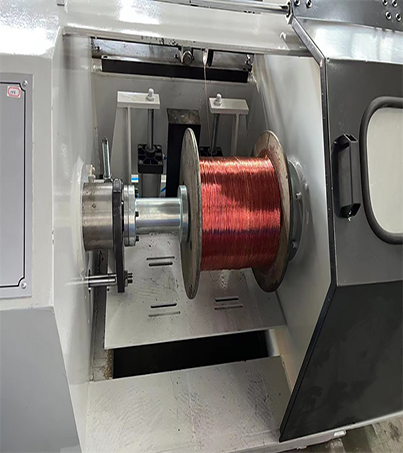

The described production line is designed for the extrusion of PVC, PP, and PE plastic particles to produce wire products.

Pp/pe Twist Tie Extruder Making Machine Fro Bread Bag

Maximum Speed: The production line can achieve a maximum speed of 300m/min. This high-speed capability enables efficient and productive manufacturing processes, helping to meet production demands and optimize output.

Finished Product Tolerance: The production line ensures a high level of precision, with a finished product tolerance of 0.01mm. This means that the produced wires will have minimal deviation from the intended dimensions, ensuring consistency and quality in the final products.

More information about us:

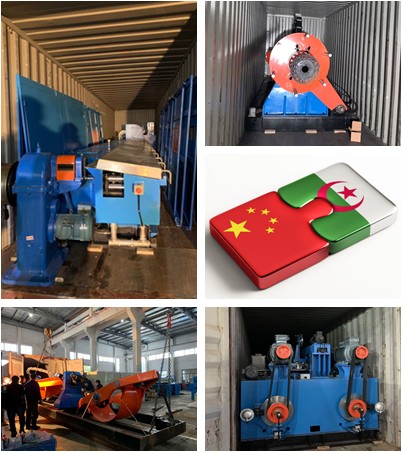

With a rich experience of over 30 years, we take pride in being a professional manufacturer specializing in the production of a wide range of wire and cable machinery. Our expertise spans the entire wire manufacturing process, from drawing to extrusion, ensuring exceptional quality and precision.

Setting ourselves apart from trade companies, we are a dedicated factory that manufactures our own machine bodies, as well as other key components and parts. This vertical integration allows us to maintain strict quality control measures, resulting in reliable and superior products.

At our facility, we have the capability to meticulously manage every aspect of our products, including pricing, quality, and delivery time. This level of control enables us to offer competitive prices without compromising on the excellence and timely delivery that our customers expect.

Inquire Form